Sida loo hubiyo qaybaha fashilka ee PCB

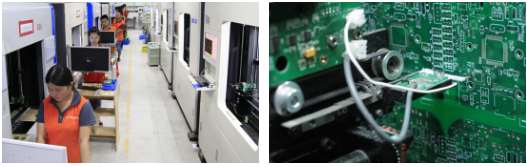

Samaynta PCB-ga iyo isku-ururinta ma adka, waxa adag waa sida loo baadho PCB ka dib marka la dhammeeyo wax-soo-saarka.

Cilladaha guddiga PCB ee caadiga ah waxay inta badan ku urursan yihiin qaybaha, sida capacitors, resistors, inductors, diodes, triodes, chips FET iyo chips kale oo isku dhafan iyo oscillators crystal.Habka ugu macquulsan ee lagu xukumo guuldarada qaybahan waxaa lagu arki karaa indhaha.Waxaa jira calaamado gubasho oo muuqda oo ku yaal dusha sare ee qaybaha elektaroonigga ah.Ciladda noocan ah waxaa lagu xallin karaa iyada oo si toos ah loogu beddelo qaybaha dhibaatada kuwo cusub.

Si kastaba ha noqotee, dhammaan waxyeellada qaybaha elektiroonigga ah laguma arki karo isha qaawan, qalabka kormeerka xirfadeed ayaa loo baahan yahay kormeerka.Aaladaha inta badan la isticmaalo ee wax lagu baadho waxaa ka mid ah: Multimeter, Capacitance meter, iwm. Marka la ogaado in danabka ama hadda qaybta elegtarooniga ah aysan ku jirin xadka caadiga ah, waxay muujinaysaa in ay jirto dhibaato qaybta ama qayb hore.Waxaan isku dayi karnaa inaan si toos ah u bedelno oo aan mar kale hubinno si aan u aragno inay caadi tahay.

Mararka qaarkood marka aan PCB-ga ku shirayno, waxaan la kulmi doonaa xaaladda in guddiga wareeggu uusan si caadi ah u shaqeyn karin laakiin ma ogaan karo dhibaatada.Xaaladdan oo kale, marar badan, qaybaha ayaa ku jira habka rakibidda, sababtoo ah iskudubarid qaybaha kala duwan, waxaa laga yaabaa inay sabab u tahay waxqabadka aan xasilloonayn.Xaaladdan oo kale, waxaan isku dayi karnaa in aan ku xukunno kala duwanaanshaha suurtagalka ah ee cilladda iyadoo loo eegayo wakhtiga iyo tamarta, iskuna day inaan yareyno aagga cilladda inta ugu badan ee suurtogalka ah.Habka kaliya ayaa ah in la isku dayo in la beddelo qaybta shakiga leh ilaa inta laga helayo qaybta dhibaatada.

Maadaama guddiga wareegga PCB uu yahay saldhigga qaybaha, guddiga wareeggu hubaal wuu yeelan doonaa cillado.Tusaale ahaan, habka wax soo saarka ee qaybaha tinning awgeed, waxaa jiri kara go'a inta lagu jiro habka daxalka PCB.Xaaladdan oo kale, haddii aysan suurtagal ahayn in la sameeyo silig, ka dibna waxaa lagu xallin karaa oo keliya silig naxaas ah oo khafiif ah.

Eray ahaan, habka cilad-saarka qaybaha PCB, waa in aan fiiro gaar ah u leenahay si aan u ogaano oo aan u xalino dhibaatada si wax ku ool ah.

PCBFuture can start at printed circuit board manufacturing, through to components supply and assembly. We are happy to supply boards and components. After the production is completed, we can provide professional PCB inspection to ensure the quality of the PCB. For more information, please email to service@pcbfuture.com.

Waqtiga boostada: Juun-19-2021